November 21, 2023

Bionetix® International is pleased to release a new brochure for the portable sanitation industry! This collection of portable sanitation products stands out from traditional treatments by putting the power of nature to work to clean, deodorize, and biodegrade. It is an excellent resource for any provider of portable sanitation services looking for practical, effective solutions to improve maintenance.

Bionetix® International is pleased to release a new brochure for the portable sanitation industry! This collection of portable sanitation products stands out from traditional treatments by putting the power of nature to work to clean, deodorize, and biodegrade. It is an excellent resource for any provider of portable sanitation services looking for practical, effective solutions to improve maintenance.

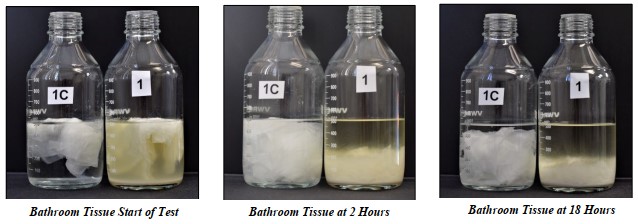

Beneficial Microorganisms at Work

Bionetix® biologicals are a perfect match for portable sanitation because they contain beneficial microorganisms that digest organic wastes such as human waste, greases, oils, undissolved soap residues, paper, and other odor-causing substances. Paired with pleasant fragrances, they not only mask odors but reduce the compounds that cause them. Better yet, Bionetix® biologicals can be adapted for use as portable toilet surface cleaners, odor neutralizers, urinal treatments, and more!

Biocide-Free Portable Toilet Deodorizers

Probiotic portable toilet treatments like those in the new Bionetix® brochure are a welcome alternative to harsh treatments of the past containing formaldehyde or other biocides. Bionetix® portable toilet treatments rely on beneficial microorganisms to digest organic waste and continue working long after application in the retention tank. They leave behind a pleasant fragrance of bubblegum, orange, cherry, or Tutti Frutti, depending on the customer’s preference. Formerly called by the PORTA-TREAT™ name, these portable toilet probiotics have been rebranded under the BIO-BOOM™ brand, reflecting the powerful biological boost they offer to holding tanks. They are available in both powder-filled-pouch (P) and liquid (L) form for use in bronze, silver, and gold applications for low to high traffic.

Portable Toilet Maintenance

The new Bionetix® brochure also contains biological treatments for general maintenance inside portable restrooms. ECO-CLEAN-ALL™ Super Concentrate is a biological surface cleaner that incorporates probiotics for extra cleaning and odor removal power. ECO-SCENT™ L Super Concentrate contains microorganisms that directly target odors and neutralize them. It can be sprayed into the air around and directly onto odorous surfaces or added to mop water for floors. Finally, URINAL BLOCKS™ enhance the standard of urinal treatment with a unique formula that helps clean away scaling problems, cure odors, prevent blockages, and digest organic waste in urinals.

Grease Trap and Septic Tank Treatments

Since many portable sanitation companies also offer grease trap and septic tank pumping services, the brochure includes specialty treatments these servicing companies can offer to their customers. ECO-TRAP™ grease trap treatments contain specialty additives to reduce oil and fat accumulation and speed up their biodegradation, thus preventing emergency blockages and reducing BOD and bad odors. ECO-TRAP™ products can be applied directly to grease traps or added through kitchen sinks and floor drains. Similarly, septic tank treatments such as ECO-SEPT™ P or FIZZY-TAB™ contain diverse microbiology designed to activate digestion of solid waste, reduce sludge buildup and pumping frequency, improve pipe purification and drain seeping, and prevent pipe and drain blockage.

Improve the Portable Sanitation Experience

While many of us do not enjoy portable sanitation facilities, we are glad they are there when we need them. With this new portable sanitation brochure, Bionetix® bids to make that experience more pleasant overall—both for those that use and for those that maintain portable restrooms and grease traps / septic tanks. Explore the new brochure to get started!

Keywords: Bionetix, probiotics, portable sanitation, porta-potty treatment, portable toilet deodorizer, portable toilet treatments without biocides, septic tank maintenance, urinal deodorizers, portable toilet maintenance, grease trap maintenance

Need a High-Resolution Photo? Please Visit: www.cortecadvertising.com

For a PDF version please click here.